What is rPET Material and Why is it Better than Regular Plastic?

rPET material is a plastic made from recycled PET products, such as water bottles and beverage containers. PET, or polyethylene terephthalate, is a common type of plastic that is derived from petroleum and natural gas. rPET material differs from regular plastic in several ways, and it has many advantages over it. In this article, we will tell you everything you need to know about rPET material, a plastic that is better than regular plastic for the environment, the economy and the society.

Manufacturing process and characteristics of rPET

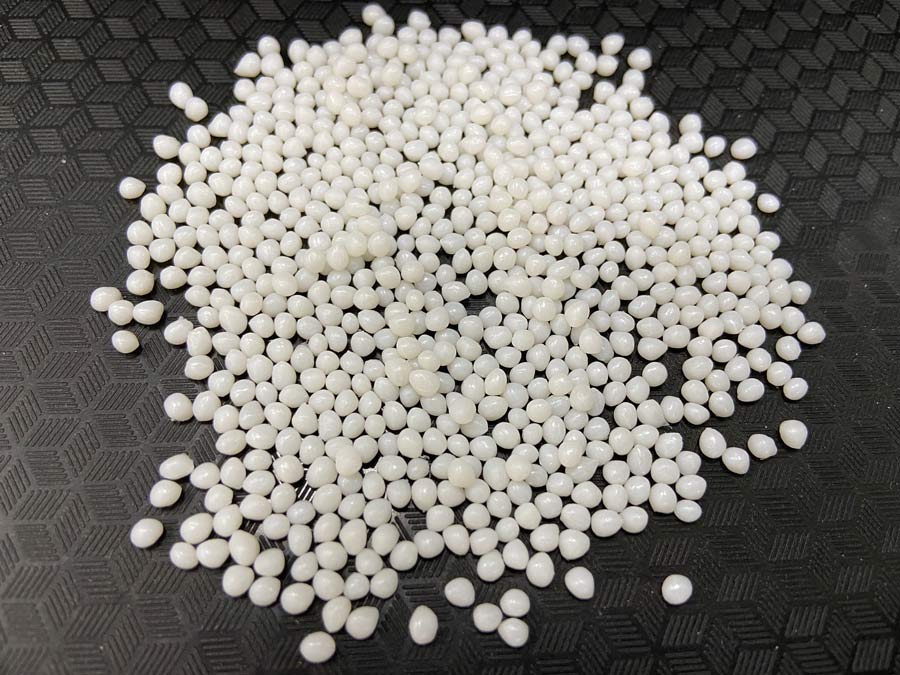

The journey of rPET starts with the collection of post-consumer PET bottles, which are meticulously cleaned, shredded, and transformed into rpet pellet. These granules are then molded into new products, ranging from packaging materials to textiles. The inherent qualities of rPET, mirroring those of virgin PET, ensure that the material maintains its integrity throughout the manufacturing process.

Recycled PET and Virgin PET – 5 Key Differences ?

Recycled PET (rPET) and Virgin PET stand as two materials with notable differences.

1. Source of Material:

rPET is derived from recycled post-consumer PET plastic, while Virgin PET is made from raw petrochemical resources.

2. Environmental Impact & Sustainability:

In contrast to the virgin PET sourced from fossil fuels, rPET is derived from recycled PET bottles, offering a more sustainable sourcing solution. The advantage lies not only in waste reduction but also in the reduction of carbon emissions associated with producing new plastics. This circular approach not only conserves resources but also diminishes the environmental impact of plastic production.

3. Material Properties:

Both rPET and Virgin PET exhibit similar material properties in terms of strength, durability, and versatility, making them suitable for various applications.

4. Consumer Preference:

Many environmentally conscious consumers prefer products and packaging made from rPET due to its sustainable and eco-friendly attributes.

5. Regulatory Support:

Governments and regulatory bodies in various countries are increasingly encouraging the use of rPET through incentives and regulations aimed at reducing plastic waste.

Application of rPET

The versatility of rPET is demonstrated by its wide range of applications across industries. For instance, major beverage companies have embraced rPET for producing bottles, reducing their carbon footprint. In the fashion industry, renowned brands are incorporating rPET-based textiles into their clothing lines, providing consumers with eco-friendly fashion choices.

Is rPET safe?

The safety of packaging materials intended for food contact is of utmost importance to ensure consumer health. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) rigorously evaluate the safety of materials like rPET. These evaluations consider factors such as potential migration of substances from the packaging to the food, ensuring that rPET containers uphold the highest safety standards.

Can rPET be recycled again

One of rPET’s most remarkable features is its ability to undergo multiple recycling cycles without compromising its quality. The closed-loop recycling process involves reprocessing collected rPET items, melting them down, and reshaping them into new products. This sustainable approach significantly contributes to the reduction of plastic waste and the conservation of resources.

Environmental Impact of rPET

The environmental implications of rPET extend beyond waste reduction. By diverting plastic from landfills and oceans, rPET actively combats pollution. Moreover, its lower carbon emissions and reduced energy consumption during production contribute to a more sustainable future.

Cost Comparison of rPET and other materials

While the initial costs of rPET production might appear slightly higher than those of virgin PET, the long-term benefits offset this disparity. The reduced environmental footprint and the growing consumer preference for eco-friendly products ultimately make rPET a cost-effective solution.

Emerging markets and the growing need for rPET

In response to heightened consumer awareness and regulatory pressures, markets around the world are witnessing a growing demand for rPET-based products. For instance, the packaging industry is transitioning to rPET packaging to meet sustainability goals and consumer expectations for environmentally friendly choices.

Conclusion

Recycled PET (rPET) material emerges as a potent force in the pursuit of a more sustainable future. With its impeccable safety record for food applications, manufacturing advantages, recyclability, reduced environmental impact, and expanding market demand, rPET takes its place as a game-changer in the realm of packaging and manufacturing. As industries and businesses strive for greener practices, adopting rPET becomes a strategic move that encapsulates innovation, environmental responsibility, and a commitment to a better world.