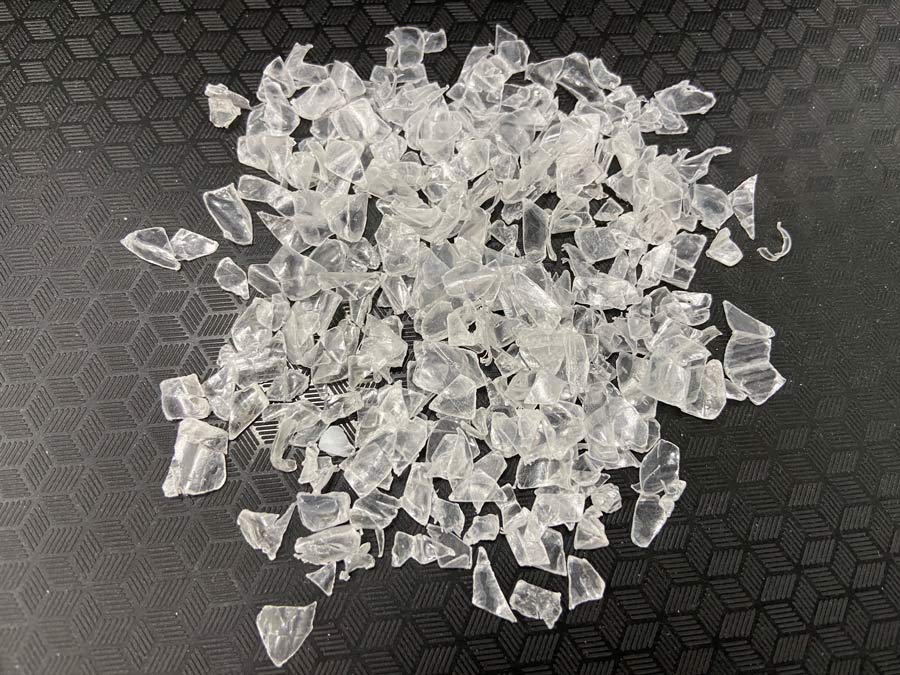

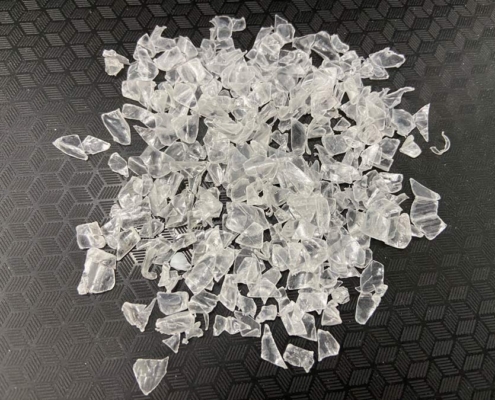

RECYCLED PET FLAKE (BF3 series)

Recycled PET flakes (rPET flakes) are made from recycled PET plastic bottles. They can be processed by blowing, injection, and extrusion to produce plastic products with strong and lightweight characteristics.

PET flakes have the following advantages:

- Renewable: PET flakes are made from recycled PET plastic bottles, so they help to reduce the consumption of virgin resources.

- Environmentally friendly: PET flakes can be recycled indefinitely, so they help to reduce plastic waste in landfills and incinerators.

- Economical: PET flakes are less expensive than virgin PET materials, so they can help businesses save money.

PET flakes are a sustainable, environmentally friendly, and economical plastic material. They can be used to produce a variety of products, such as clothing, bags, bottles, and containers. PET flakes are a green choice that can help us reduce plastic pollution and protect the environment.

Recycled PET flake properties:

PET flakes are a high-performance, recyclable plastic material made from recycled PET plastic bottles. They have a number of desirable properties, including:

- Strength: PET flakes are stronger than many other plastics, making them ideal for products that need to be able to support weight.

- Durability: PET flakes are durable and can withstand harsh environmental conditions.

- Transparency: PET flakes are highly transparent, making them ideal for products that need to be clear and see-through.

- Non-toxicity: PET flakes are non-toxic, making them ideal for food and beverage containers.

- Recyclability: PET flakes are recyclable and can be recycled indefinitely.

rPET Flake applications:

Food and beverage containers: PET flake is a popular choice for food and beverage containers because it is strong, durable, and non-toxic. It is also recyclable, which helps to reduce plastic pollution.

- Cosmetic containers: PET flake is also used in cosmetic containers because it is clear and see-through, which allows the contents of the container to be easily seen. It is also non-toxic, which is important for products that come into contact with the skin.

- Pharmaceutical packaging: PET flake is often used in pharmaceutical packaging because it can also be sterilized. This makes it a safe and reliable material for packaging medications.

- Industrial products: PET flake is used in a variety of industrial products, such as conveyor belts, electrical components, and automotive parts. It is not only strong, durable, but also resistant to chemicals, making it a versatile material for a wide range of applications.

- Building materials: PET flake is also used in building materials, such as insulation and roofing tiles. It is a sustainable and recyclable material that can help to reduce the environmental impact of construction.

Product Details

There are two grades of our recycled PET flake. They are BF3-200 and BF3-100 and with key specifications as below , for more Rpet flake details ,please refer to our Technical data sheet.

PVC

| BF3-200 | BF3-100 |

|---|---|

| ≦20 ppm | ≦50 ppm |

Yellowish Flake

| BF3-200 | BF3-100 |

|---|---|

| ≦2000 ppm | ≦3000 ppm |

Other Color PET

| BF3-200 | BF3-100 |

|---|---|

| ≦400 ppm | ≦600 ppm |

FAQ

Q: What is the price of PET Flakes?

The price of PET Flakes depends on the following factors:

- Quality of PET Flakes

- Color of PET Flakes

- Size of PET Flakes

- Quantity of PET Flakes

- Supplier of PET Flakes

Q: How to ensure the quality of PET Flakes?

When ensuring the quality of PET Flakes, you should note the following:

- Request the supplier to provide a quality certificate.

- Inspect the quality of PET Flakes before delivery.

- Establish a long-term cooperative relationship with the supplier, so that you can better understand the supplier’s product quality.